Quality Control

In addition to the quality management system (AS9100) for the aerospace and defense industry products, we acquired quality certifications on thermal treatment, labs, ultrasonic inspections, etc. and through this, we are operating a thorough quality control system to realize quality levels of global standards.

Lab inspection and measurements

We ensure quality through various tests and measurements such as 27 element component analysis for high-strength aluminum alloy chemical component management, composition homogeneity inspection before and after extrusion through 3D measurements and etching tests, and temperature measurement of dissolution and extrusion processes.

Component analysis

3D measurement (CMM)

Etching test

Securing thermal treatment quality

In order to thoroughly observe global standard regulations on thermal treatment and hot-temperature measurement such as AMS2772, AMS2750, etc., we secured outstanding thermal treatment quality through tensile strength tests, hardness tests, and electric conductivity tests.

Tensile strength test

Hardness test

Electric conductivity test

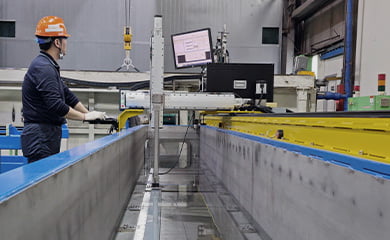

Ultrasonic test

In order to detect defects in aluminum products, the pulse reflection method is used that helps determine the size and location of defects by projecting ultrasonic waves. In addition, submersing automatic equipment and contact-type manual equipment are used according to customer requests.

| TYPE | IMMERSION(TYPE1) | CPMTACT(TYPE2) | |

|---|---|---|---|

| Model | USIP40 (GE I/T) | NDT PA (NDT ENG) | EPOCH-XT, EPOCH-600 (OLYMPUS) |

| Probe | 0.2-30MHz | 0.2~20MHz | 1-20MHz |

| Mode | Multi A and C-scan | A and B-Scan, C-Scan | Pulse-Echo A-scan |

| Tank size | W 1,726 x H 1,654 x L 8,600mm | W 800 x H 710x L 11,500mm | N/A |

| Scope | Min. OD12.7~850mm x 7,300mmL, and profiles | Up to W570 x 10,000mm profiles | Min OD12.7 ~ 860mm and profiles |

| Applicable | AMS-STD-2154 and ASTM B594 (class AA, A, B, C) BOEING BAC 5439, BSS7052, BSS7055(class AA, A, B, C) |

AMS-STD-2154 and ASTM B594 (class AA, A, B, C) |

|

USIP40

NDT PA

Non-destructive inspection