Process Technology

SeAH Aerospace and Defense secures unrivaled expertise and competitiveness regarding high-strength aluminum alloy and forged products, and it produces and supplies the widest range of aluminum alloy products in the Republic of Korea.

Casting

Casting

The casting process is composed of the melting, alloying, component analysis, degassing, casting, and homogenization procedures. In addition to alloys that facilitate all industrial specifications with1XXX~7XXX, customer tailored alloys are also produced to supply extrusion billets as well as large casting billets at various sizes.

-

01

Dissolution equipment

The dissolution equipment is composed of two 10-ton units and uses gases.

-

02

Casting equipment

Casting equipment uses 5”, 7”, 9”, 11”, 15“, 18”, and 35” billets.

-

03

Homogenization equipment

The homogenization equipment is made up of one 25-ton unit and one 15-ton unit, and it performs billet homogenization.

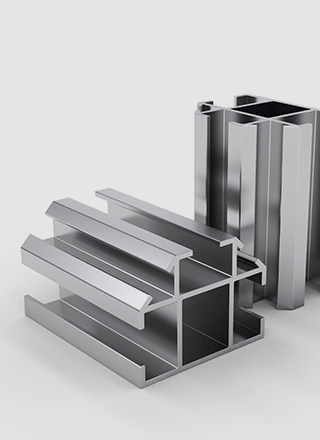

Extrusion

Extrusion

Extrusion production is possible as rods, rectangular members, and section members in the extrusion process. Extrusion molds are produced independently and through corrections and management, optimal extrusion conditions are established and managed to have outstanding metallic structures.

-

01

Extrusion equipment

Extrusion equipment include the direct/indirect method 4200 tons, direct method 2200 tons, 1800 tons, 1650 tons, and 660 tons extrusion equipment.

-

02

Customized production

Minimum of DIA9 to maximum DIA144.8 rods can be produced. In addition, rectangular members, section members, and tube members can be produced upon orders.

Solution

Thermal treatment

The thermal treatment process is composed of the basic process that meet specifications according to the requests of customers and follow-up processes such as imprint, calibration, and cutting. In particular, it produces materials with stable and outstanding strength through the best thermal treatment processing management abilities. It manufactures products at sizes of DIA12.7~DIA66.7 based on rod materials through the imprinting process.

-

01

Solution thermal treatment

We operate 4 vertical solution thermal treatment furnaces that satisfy AMS 2772 and AMS 2750 requirements and that can perform water cooling and oil cooling.

-

02

Stretcher

After solution thermal treatment, 50-ton, 300-ton, and 600-ton stretchers are used to remove the products’ stress.

-

03

Artificial prescription thermal treatment & annealing

One horizontal aging thermal treatment furnace and two aging and annealing thermal treatment furnaces that meet AMS 2772 and AMS 2750 requirements are operated.